EXAMPLES OF USE

It is surely not easy to determine when the first conveyor belt was made.

A better question would probably be: When did somebody put something on a transmission belt to bring it from A to B?

Those days the carcass was made of a high number of cotton plies.

One story is that Oliver Evans in 1795 described "a broad endless strap of thin pliant leather revolving over two pulleys in a case or trough". Maybe this was the start?

THE FIRST CONVEYOR BELT

An even stronger belt, ST 10000, has been commissioned at Codelco's Chuquicamata underground system in 2019.

It also conveys crushed copper from underground to the surface in a 7 km underground tunnel with two conveyors, having a total lift of 1 km.

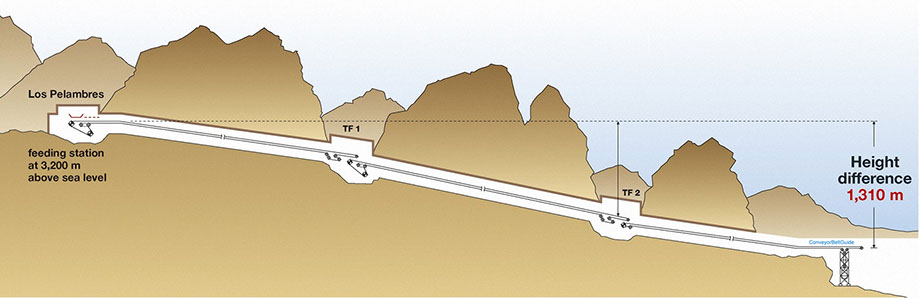

The photo shows the ST 7800 steel cord conveyor belts, operating on two long distance downhill conveyors at the Los Pelambres copper mine in Chile.

Coordinates: 31°43'2.02"S 70°28'50.93"W

Since it is downhill conveying, the system generates more than 100 million kilowatt-hours per year at a load of 11.000 t/h.

The disk breaks have a diameter of 2,5 m. The length of the 3-part system is 12.700 m.

Almost the complete belt is operating in tunnels to protect it from the danger of avalanches in the Andes.

THE STRONGEST CONVEYOR BELTS

This is one of the biggest bucket-wheel excavator worldwide, operating at RWE lignite mines in Germany.

It has a capacity of 240.000 cbm per day.

A dozer taken up by the bucket wheel like a toy.

The conveyor belts used on these giants are 3200 mm wide.

They are carrying up to 40.000 t/h of overburden and lignite, which makes them the highest capacity conveyor belts worldwide.

Note: Some of the belts that have been used on such machines have a total breaking strength of 2200 tons, because of their width of 3200 mm, making them the strongest on earth, if one looked at total belt strength.

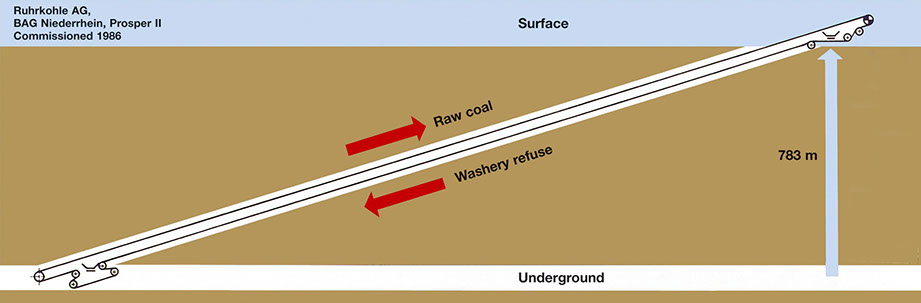

The strongest underground conveyor belt was operating in a very interesting installation.

It was not only r.o.m. coal that is conveyed from 800 m underground to the surface but also, simultaneously, tailings from the washing plant back underground.

The belt is 1400 mm wide, type ST7500, with 10 plus 12 mm covers including protecting reinforcements in both sides.

It is self-extinguishing, meeting world's most stringent requirements.

End of 2018, this mine including the conveying system was shut down forever.

Coordinates: 51°36'7.77"N 6°53'16.25"E

This revolutionary system was commissioned in 1986 at the Prosper Haniel hard coal mine in Germany.

The capacity is 2000 t/h on the top run (uphill) and 1000 t/h on the bottom run (downhill).

The centre distance is 3745 m, the gradient is 12,3°. The belt runs at a speed of 5,5 m/s.

It has the first gearless belt conveyor drive with two 3-phase current motors. Such cycloconverter-fed drives, offering advantages like high availability, reduced energy consumption and lower maintenance costs, have later been used for high-capacity conveyors at Los Pelambres and Antapaccay copper mines.

Please also see video on Homepage.

THE HIGHEST CAPACITY CONVEYOR BELTS

It is not easy to keep abreast of all the record belts. It seems there is still no end for improvements.

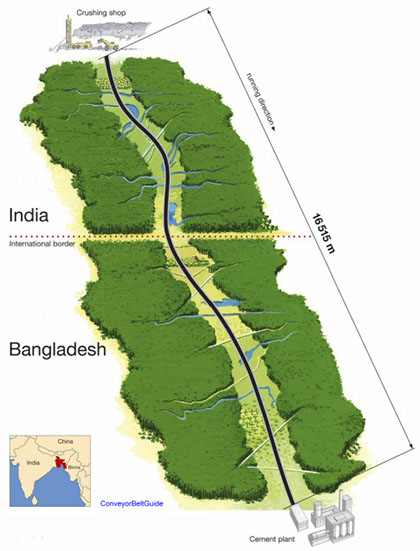

One of the longest single flight conveyor belts - see illustrations - is bringing limestone from a mine in India to a cement plant in Bangladesh. It was commissioned in 2005.

There are no intermediate drives or transfers between both end pulleys.

The belt is 35 km long, 800 mm wide, type St 2500.

Another record length belt was commissioned in 2015 at Sasol's Impumelelo project in South Africa. The conveyor length is 27 km, belt width 1200 mm, type St 2000 with 7+5 mm covers. The capacity is 2400 t/h at 6,5 m/s. The belt was produced in China.

The entire conveyor in India/Bangladesh is built on pillars.

Coordinates: 25°2'51.42"N 91°39'32.94"E

The longest belt conveyor system globally has been in operation in Western Sahara since the middle of the last century.

One can easily detect it by the phosphate spillage south of it.

It is conveying phosphate from the Bu Craa mine to the coast at El Aaiún.

The system consists of 11 flights of up to 11,7 km, totalling to a little more than 100 km conveying length.

The capacity is 2000 t/h. The belt type is St 2500. Belt width 1000 mm.

Coordinates: 27°02'48.49"N 13°24'43.07"W

A top view of one flight

THE LONGEST CONVEYOR BELT SYSTEM